Soft Extrusion - The cheap solution for better quality feed

Soft Extrusion - The cheap solution for better quality feed

IntroductionCrevetec wants to provide a total solution for ecological (and economic) production of shrimp. This means shrimp should be produced with maximum efficiency of feed. Pelleting of shrimp feeds is not really the best possible technology. To obtain a good water stability artificail binders like ureaformaldehyde are often added to the feeds. This binder give not only a false proteins reading, but also binds with the NH2 groups of amino acids, reducing the digestibility of the proteins. These feeds also contain high and expensive starch like wheat flour while shrimp are very poorly utilisers of starch.A better technology is therefore wishfull. Extrusion can increase the formulation flexibility, but at the same time, the high cooking temperatures are not really favouring protein digestibility.

What is soft extrusion ?Soft extrusion is combination of different techniques. Pellets are produced with a forming extruder and than dried. During the extrusion raw materials are not heated above 80°C. The water stability of the pellet is formed by a combination of cooking the starch and coagulation of proteins. Fresh non-coagulated proteins can be mixed before extrusion. The low temperature processing and utilization of non-coagulated proteins favors the digestibility of proteins. The result is a soft and flexible pellet. This pellet can be hardened if wished by drying completely.Products which can be produced The customer has the choice to produce a semi-moist pellet or a dry pellet. A dry pellet can also be coated

afterwards with hydrolyzed proteins to produce a semi-moist pellet. This production technique can be used

for shrimp and fish species. To produce floating feeds, the pellets should be dried completely.

Small pellet particle sizes of 0.6, 1.0, 1.5 and 2 mm can be produced, so no crumbling is required for

starter feeds or shrimp feeds. Bigger pellets of 3 to 12 mm can also be produced.

The customer has the choice to produce a semi-moist pellet or a dry pellet. A dry pellet can also be coated

afterwards with hydrolyzed proteins to produce a semi-moist pellet. This production technique can be used

for shrimp and fish species. To produce floating feeds, the pellets should be dried completely.

Small pellet particle sizes of 0.6, 1.0, 1.5 and 2 mm can be produced, so no crumbling is required for

starter feeds or shrimp feeds. Bigger pellets of 3 to 12 mm can also be produced.

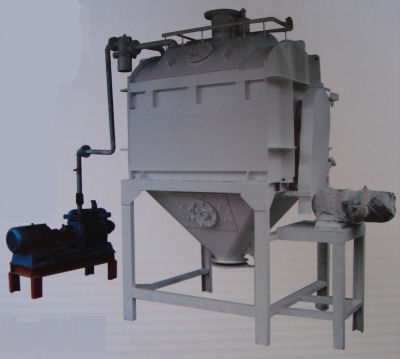

FlowThe production line consists of the following steps:Intake of raw materials – first mixing – grinding in pulverisor with classification and sieve – second mixing with addition of liquids (oil, lecithin, fresh proteins) – soft extrusion – drying/conditioning – cooling – sieving – vacuum coating (optional) – packing The exact configuration of the producion line can be adapted according to the products which will be produced and the existing machinery. MachineryCreveTec has established a strategic cooperation with Xiamen Ying La Machinery Manufacturer Co. to manufacture suitable machinery. The following equipment can be offered:

|